What is vibration? – Generating vibration and vibration testing

Why do we need artificial vibration generation? Let's learn purposes and importance of vibration testing.

What is vibration testing?

Experiment for designing products, stress screening for quality control

In vibration testing, the vibration environment to which products will be exposed to in real use is reproduced. Products are tested in this environment to judge their durability or check for improvements.

There are two types of vibration testing

"Vibration Experiment"

Vibration testing that is used to test a sample or representative model of volume production. Used to improve the product design.

"Vibration Stress Screening"

All production products are tested to eliminate faulty units and approved good units. May be compulsory in certain industries.

In the case of car

Vibration is inseparable from a car's motion. There is a lot of influence from vibration in long term driving and off-road driving. Observation for durability and influence of vibration is an important process to obtain the reliability of products.

All of the possible environments that a car will experience in its lifetime are reproduced during vibration testing.

Investigations occur for vibration damping and, motion characteristics of the tire, car frame and car body. Investigation also occurs into the influence of vibration on car electronics, such as radios and stereos.

Also, simulation testing of vehicle seats and safety devices is performed.

In the case of a Portable CD Player

With equipment such as portable CD player, most failures are likely occur while it is being carried. 'Portable' is the most important advantage of such equipment. Vibration testing is essential during product development. For example, the worst vibration may be found while cycling on a bumpy road with the portable CD player in a bicycle carrier basket. In fact, IMV's Test Laboratory is required to reproduce vibration and shock experienced during the bumpy cycle ride using it's vibration test equipment. The test equipment is operated continuously where 30 minutes of testing is equivalent to one day of cycle riding. This test increases product reliability and reduces warranty claims.

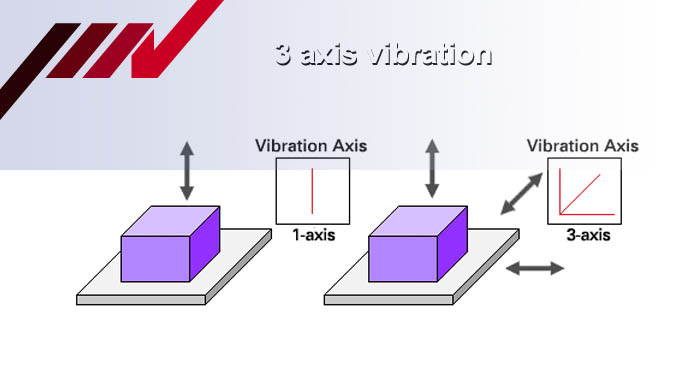

Real vibration is generated by 3-axis vibration

Making vibration similar to real vibration

The purpose of vibration testing is to reproduce actual vibration measured in the field. The vibration that products are exposed to is not just in one direction, but is complicated by two or even three simultaneous directions of vibration. Multi-axis excitation by 2-axis or 3-axis enables the realization of vibration characteristics which are not found in single axis excitation and to save test time.

IMV makes it possible to operate vibration testing not only for 2-axis simultaneously or 3-axis sequentially but also for 3-axis simultaneously. IMV is supporting the improvement of quality and safety for many products by reproducing vibration that is similar to actual vibration experienced in the field.