How does IMV’s ECO System save energy and money?

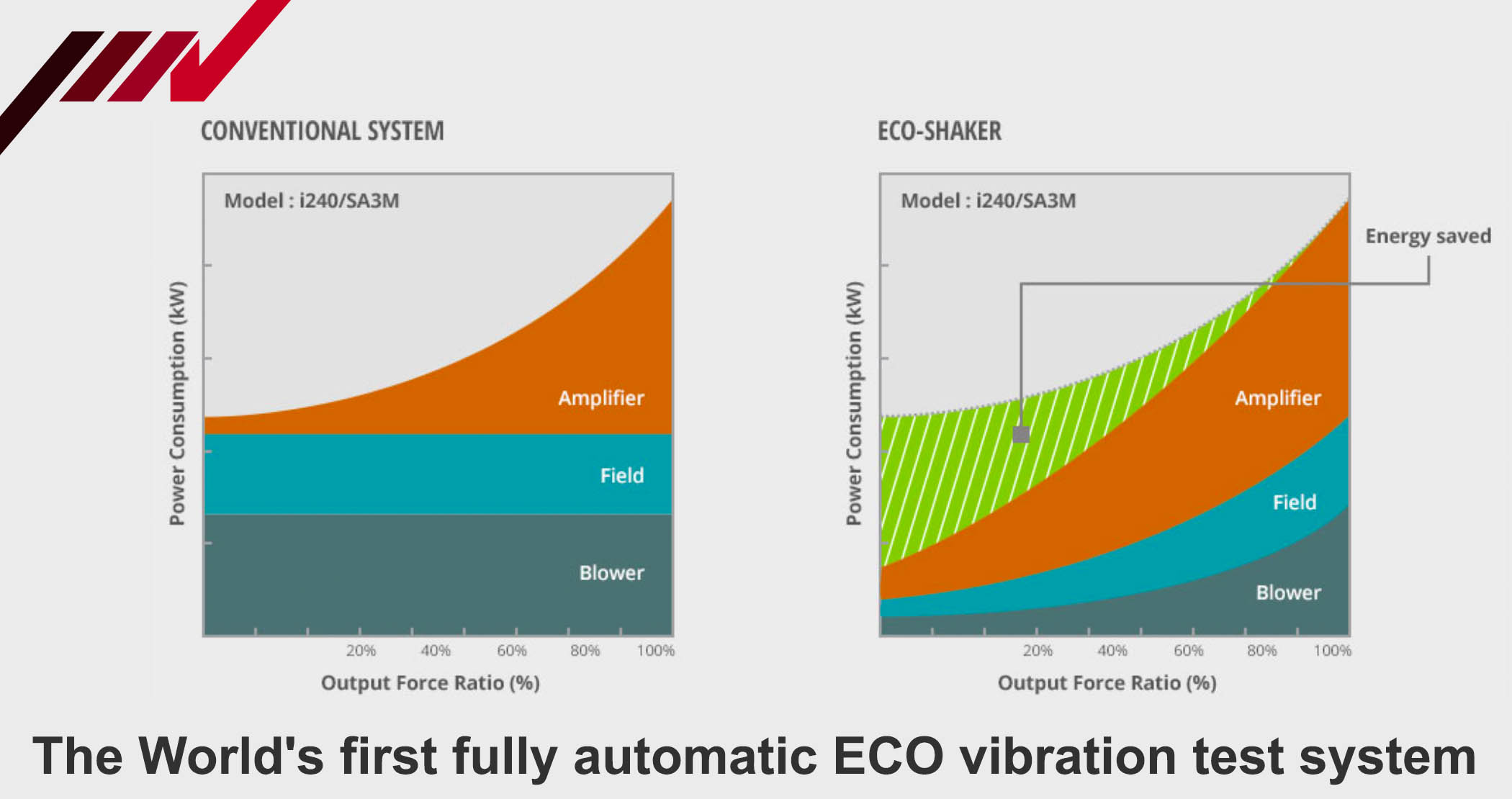

Conventional shaker systems set the field power and blower speed to the nominal settings as soon as the system is started. Only the armature power is varied according to the force required for the test.

IMV’s ECO-shaker system constantly monitors the force required to operate the vibration test and by using the high frequency power converters discussed above, the ECO-system automatically adjusts the field power and cooling blower speed to run at the point of minimum energy consumption.

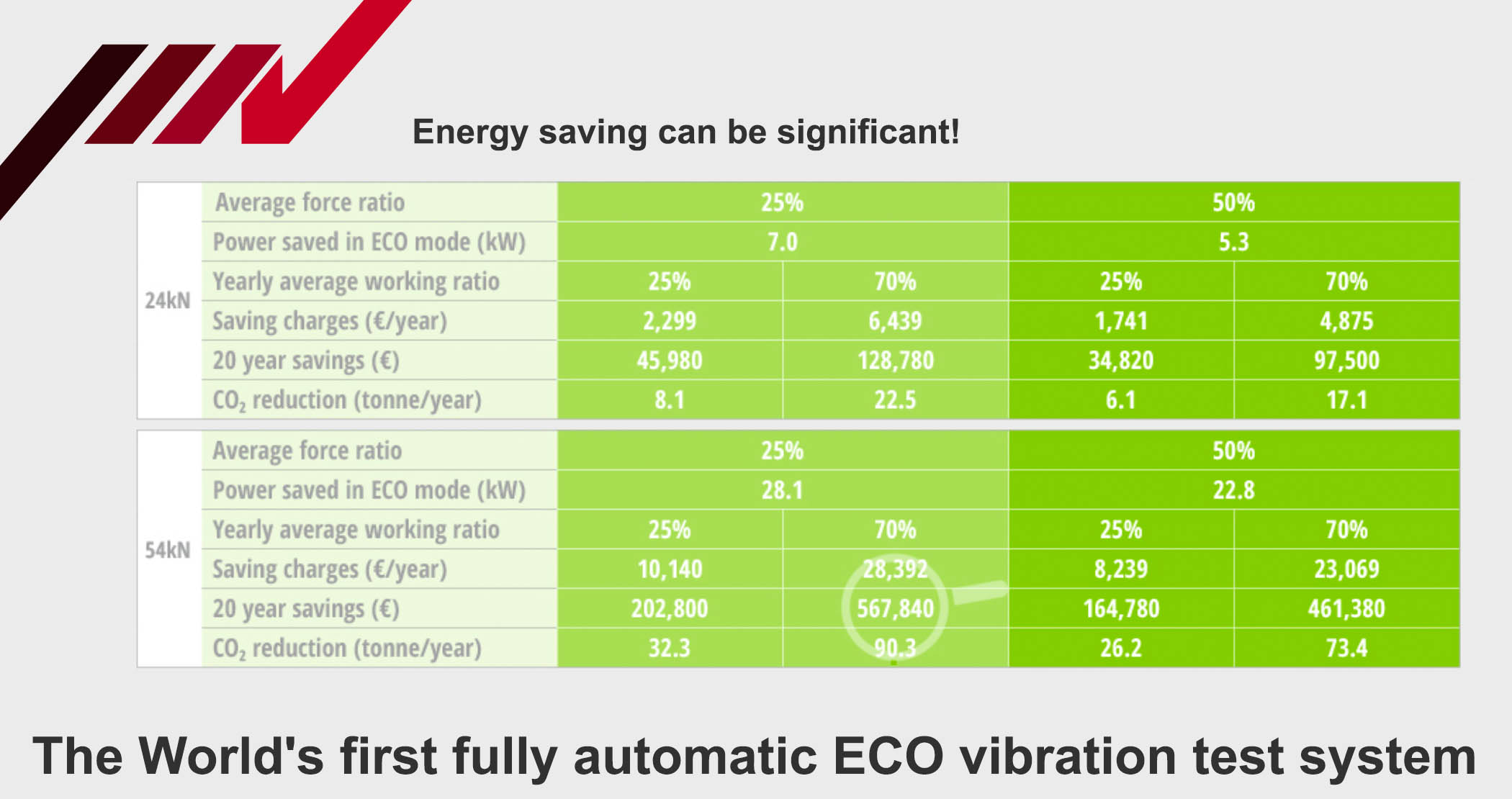

Energy saving can be significant. Some examples of running IMV’s ECO-shakers are shown below. This is a real cost saving and keeping money in the bank account. These calculations are based on actual shaker performance parameters.

When saving energy, IMV’s ECO-system is also saving CO2, helping to reduce your Company’s carbon foot print. the tables above show this CO2 reduction.

The ability to maximise the energy saving and continuously operate the shaker in a completely safe region throughout all of the possible operating modes is based on years of research by IMV Corporation on detailed analysis of shaker system design and performance.

For further information, please, contact us!