What is vibration? – What is the need for vibration measurement?

Measuring vibration. What can we find out by measuring vibration? Let's find out the significance of vibration.

What is the need for vibration measurement?

Vibration may influence the durability and reliability of machinery systems or structures and cause problems such as damage, abnormal stopping and disaster. Vibration measurement is an important countermeasure to prevent these problems.

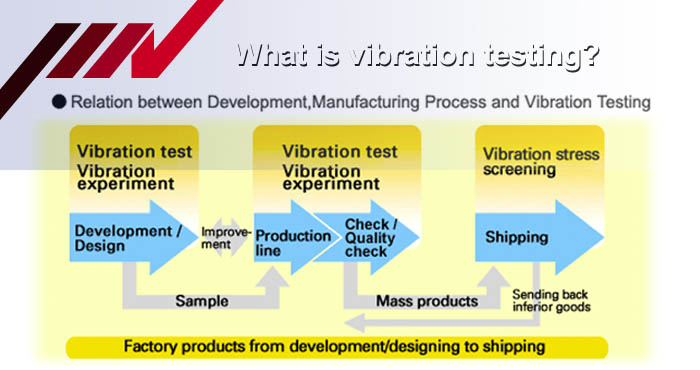

Research and Development

To develop and design more reliable products, vibration measurement and shock measurement is operated in testing of samples or finished products.

Improving the Quqlity of Product

To solve the problems caused by vibration and improve the quality of products, vibration measurement is operated for a sample, of mass-produced or all completed products to eliminate inferior pieces and produce satisfactory ones.

Safety Management in Factoies

To prevent the breakdown and trouble from machinery, vibration in measured periodically and compared to the vibration at initial condotion or at normal condition after the maintenance for judging the deterioraten oc equipment.

Maintenance of Production systems

Vibration measurement is used not only when the problem occurs but also when the daily maintenance is performed. The production system is kept in operation by detecting the deterioration or possible failure of a part through adverse vibration patterns.

Inspection of Pollution

To inspect the influence of vibration on people at a specified factory, construction site, or through road traffic and trains, vibration measurement is performed to judge whether it is within the allowable level.

Vibration tells us many things

Faulty machinery is detected by vibration!

Suppose that an abnormal vibration is generated when three cogwheels, each having different numbers of teeth are rotating in a gearbox. There must be a fault somewhere. Where does it occur? In such a case, the fault can be detected by vibration measurement.

At first, the vibration frequency of the gearbox is measured. Next the number of rotations per second is calculated for each of the three cogwheels. The vibration frequency of the gearbox should be a multiple of the number of rotations per second of the faulty cogwheel. The number of faulty teeth can be calculated from the multiple of the vibration frequency. In that way, the fault in the machine has been detected by analysis of the vibration measurement.